Description

High performance pe/pp masterbatch compounding pelletizing production line has excellent mixing performence, good self-cleaning performance and flexible modular configuration characteristics which make them suitable for processing different types of material. they are extensively used in the polymers processing, food staff processing and chemical produts, especially for various of high malecular materials.

Application for water-ring hot face production line

1. Filling master batch: PE, EVA, etc. + caco3, talc, filling modified and carbon black etc.

2. LDPE, HDPE, LLDPE, MDPE, drivepipe, insulation material, crosslinking material,cable coating material , thermal contraction pipe material.

3. PPR pipe compounds, PE crosslinking tube material, TPR, TPU thermoplastic elastomer, EVA and hot melt additives.

4. Color mater batch: PE, ABS, PS, EVA masterbatch, etc.

5. ABS, EVA flaming retarding master batch, etc.

6. PE, PP, PS filling and biodegradable masterbatch, etc.

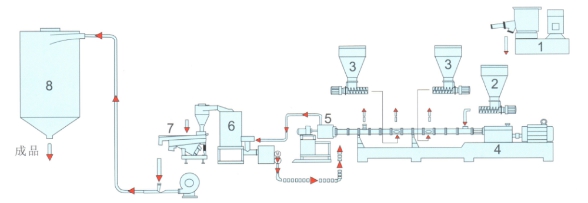

1.high-speed mixer 2. main feeder 3. side feeder 4. twin-screw extruder 5. water trouh

6.centrifugal off-water machinery 7.vibrating sieve 8. product containera

Before-sale

1. Introduce products and applications detain

2. Recommend suitable solution

3. Provide with reference in formation

4. Offer lab for test

During manufacturing

1. Provide with layout and engineering conditions

2. Inform the project processing status

3. Offer other documents

After-sale

1. Provide with installation ,commissioning and training

2. Register and record customer information

3. Offer spare parts

4. Provide with necessary technical support for new application

5. Visit customer regularly and correct information