Description

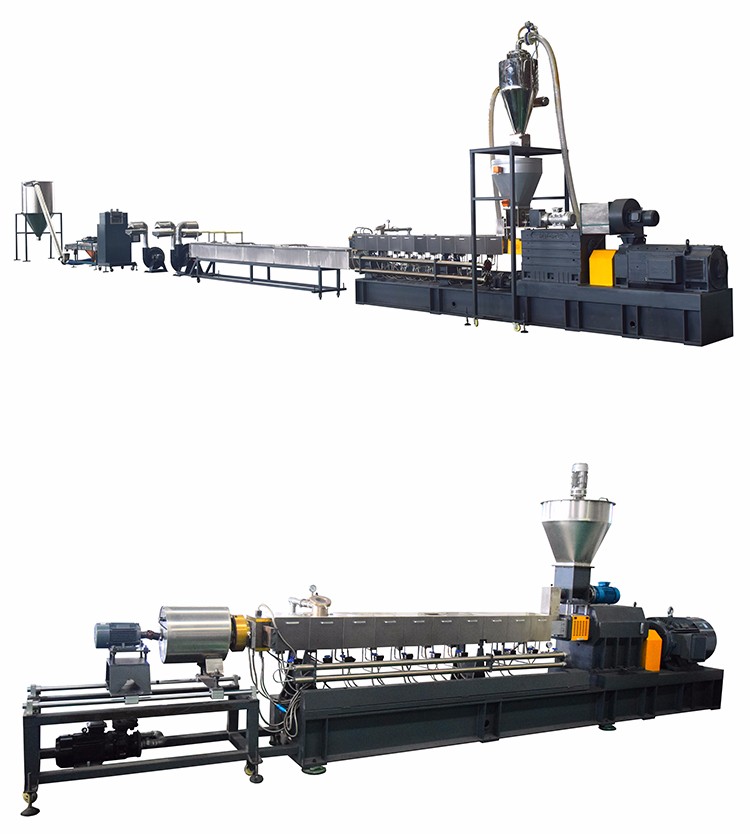

Product Description of Black Masterbatch Production Line

Parallel co-rotating twin screw extruders have excellent mixing performance,good self cleaning performance and flexible modular configuration characteristics which make them suitable for processing different types of material systems,and are extensively used in fields of polymer processing ,foodstuff processing and chemical products, especially for various high molecular materials.

In most cases ,parallel co-rotating twin screw extruders are used as mixing equipments ln processing high molecular materials,the modification process and masterbatch preparation of polyolefin materials and engineering plastics require sufficient and intensive mixing,which differs depending on material systems, Excellent equipment performance,reasonable mixing process, advanced combination technique and rich processing experience are the key factors determining the success and efficiency of mixing.

Application

a Masterbatch

b Plastics modification

c Fiber glass reinforcement

d Cable compounds

e Alloy plastics

f Powder coating and toners, etc

Our advantages of twin screw extruder :

1, Modular principle design for screw configuration andbarrel setup makes combination and cleaning convenient ,also easy to adapt to customers’ requirements .

2, Different kinds of pelletizing modes can meet specific material properties: water-cooling strand pelletizing,

air-cooling hot-cut pelletizing, water-ring pelletizing,under water pelletizing, etc.

3, Screw elements and kneading blocks are made of high tool steel , with high corrosion-resistant and high wear-resistant.

4, Barrels are made of high quality nitrided steel ,corrosion proof and antifriction.

5, Vacuum system fulfills devolatilization to ensure the quality of polymer processing.

6. Famous brand parts and our own processing lathe.

7.CE & ISO & TUV certification

SW Series Co-rotating Twin Screw Extruder are widely used in the compounding modification field, like the filling, reinforcement, toughening of plastics, engineerplastics and thermoplastics, and also for the special fibers and adhesive process according to the max screw rpm and its torque rating,main products are classified as sw series.