Description

The Characteristics of The Twin Screw Plastic Extruder Machine :

1.The gearbox

· New-style project of parallel three-axises driving makes the convey axis, convey chain, decelerate and the torque assignment get together, which keep it compact, and the key bearings are imported.

· The select material of drive components is dainty, including super intension alloy cementiteing steel, cementiting and quenching, gear grinding technics, strengthening of tooth face. So they can ensure high torque, high precision and low noise.

· Soakage and coerce lubrication integrate smoothly. When the hydraulic circuit is over pressed, it alarms.

2.The feeding system

· Metering feeders are equipped with single screw, twin screw, hollow screw, forced-feeding, side feeding, liquid-adding system,etc.

3.Screw

· The screw elements and then kneading blocks are designed accurately, by precise processed, agile combination, with interchangeability, which can fulfill efficient self-cleaning, transmission, compounding, pressure-forming.

· The screw material is made of high tool steel 38CrMoALA or W6Mo5Cr4V2 by special heat-treament.

4.The barrel

· Eurostyle rectangle barrel, reflux refrigeration is optimized and disposed, which makes temperature difference in C areas smaller.

· According to the material and special techinics demands, the material of cylinder can use high quality nitrided steel, corrosion proof or antifriction with corresponding process.

5.The heater

· Innovated design of heater tightened style insures high efficiency of heat transfer and high longervity of heater.

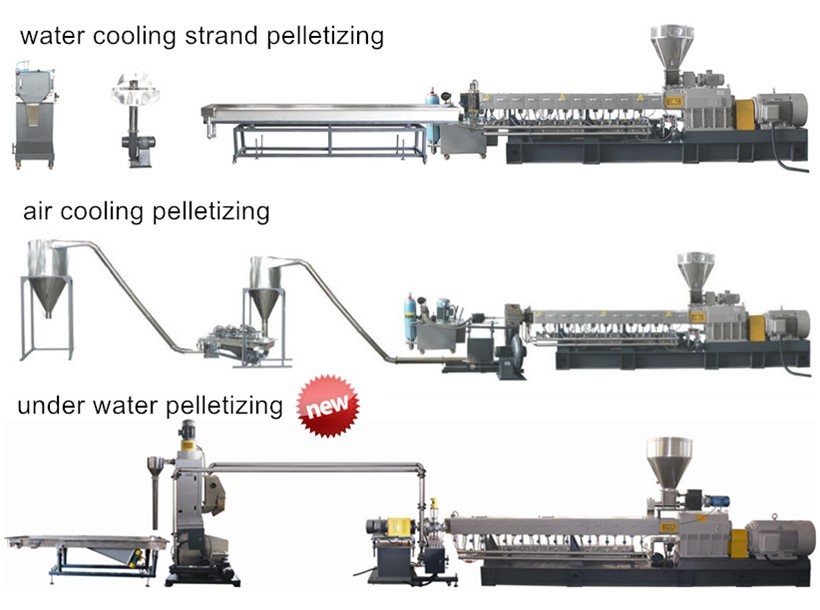

6.Pelletizing

· Variou modes of pelletizing, such as water-cooling strand, air-cooling pelletizing, water-ring pelletizing, under water pelleting, etc.

Application:

1.PE,EVA etc. ,filled with CaCO3,talc,TiO2,carbon black etc.

2.Cable sheath , cable insulation compounds of LDPE,HDPE,LLDPE,or MDPE;

3.PPR pipe compounds,PE compounds for crosslinked pipes;

4.TPR,TPU TPV thermoplastic elastomers; EVA and hot-melt adhesives

5.Color concentrates of PE,ABS,PS,EVA etc;

6.Flame retardant masterbatcher of ABS,EVA etc;

7.Masterbatches with PE,PP,PS etc. As carriers for degradation applications.